Steel plants and metal smelters

Vacuum extraction of scale in a steel plant

Vacuum extraction of scale in a steel plant by a 55 kW KS-550 unit with an filter separator FA-24 under the cooling rack. The scale is extracted manually and discharged dust free into containers. The containers are pulled out from under the filter separator with a rail system. The scale is then recycled in the steel plant.

KS-550

Vacuum cleaning in steel plants

An S-3 is used to clean the production area in a steel plant. The unit is either connected to local pipeline systems in order to clean higher levels of the structure or is brought directly to the workplace. The extracted material is discharged downwards form the 500 litre collection container of the S-3 with the help of a fork lift truck.

VU-1355

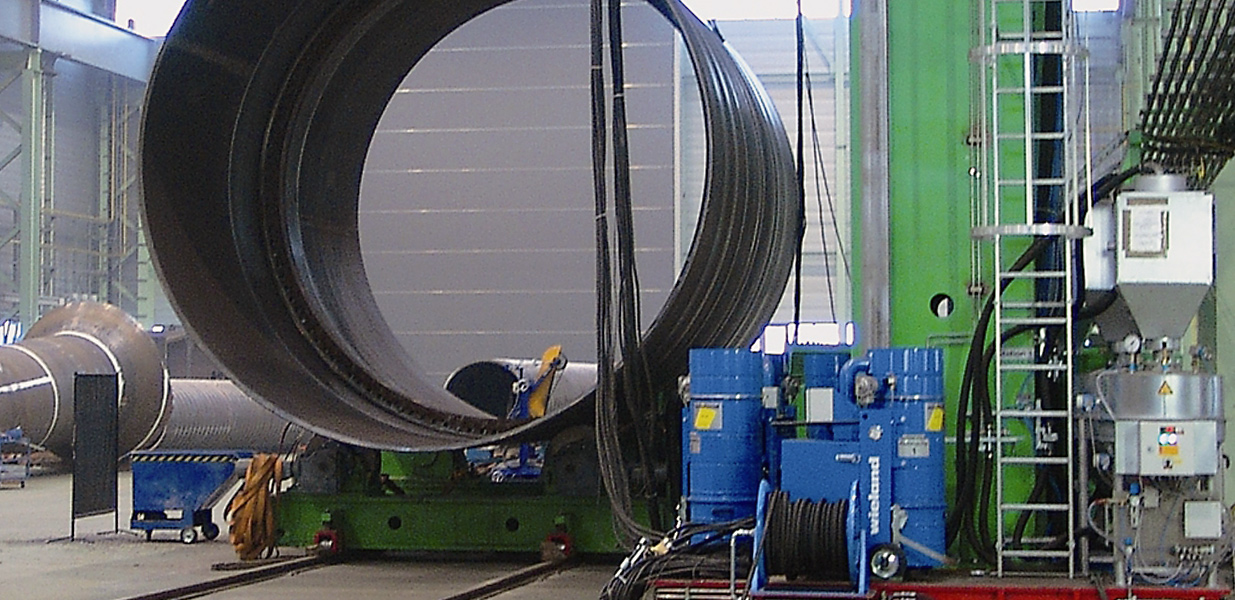

Extraction of large amounts of suction material in steel plants

Larger amounts of suction material are extracted with a DN 80 flexible hose. Thin layers, e.g. at the annealing line are usually extracted with DN 50 or DN 60 hoses. The pipeline system is dimensioned accordingly. Several operators can work simultaneously. The suction power is created by a 30 kW KS-300 unit with a rotary piston pump. The suction material is collected centrally with the help of a FiltroJet filter hopper. It is discharged downwards into an existing storage silo.